When component replacement outweighs repair costs

Deciding whether to repair or replace a failing heating component involves safety, long-term efficiency, and service practicality. This article outlines clear indicators professionals use during inspection to determine when replacement is the more sensible option, and what to check before scheduling work.

Deciding whether to repair or replace a heating component requires balancing immediate expense with long-term performance and safety. Regular inspection can reveal patterns—frequent failures, escalating diagnostics codes, or parts that are no longer supported—that tip the balance toward replacement. Understanding how age, energy efficiency, and risk (especially for combustion-related parts) affect lifecycle cost helps homeowners and local services make choices that reduce unexpected breakdowns and maintain reliable warmth.

When does inspection indicate replacement?

A systematic inspection that includes diagnostics and a review of service history often reveals whether a single repair is appropriate or if replacement is advisable. Look for recurring failures, corrosion, repeated blower or ignition faults, compromised flue integrity, and evidence of poor combustion across visits. If an inspector finds multiple failing components at once, or wear that will soon affect safety or efficiency, replacement can be more economical than repeated repairs.

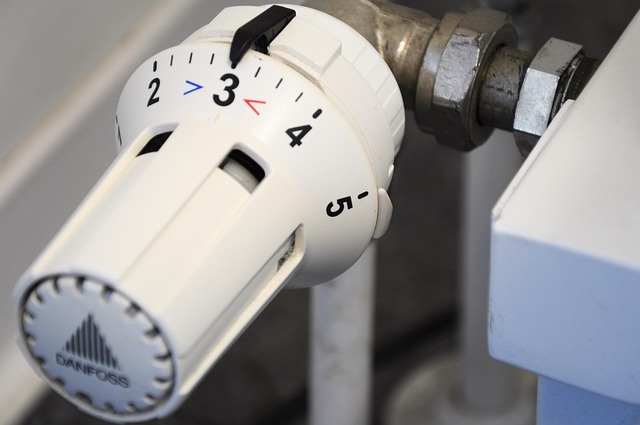

How does thermostat condition affect efficiency?

A malfunctioning or outdated thermostat can cause persistent inefficiency even when the heating system otherwise operates. Calibration, sensor accuracy, and compatibility with zoning setups and modern sensors matter. If a thermostat repeatedly fails diagnostics, cannot be calibrated effectively, or lacks features needed for proper scheduling and zoning control, replacing it may restore comfort and improve energy use more than repeated sensor or calibration work.

Are filters, airflow, vents, and blower beyond service?

Filters and vents are routine maintenance items, but deteriorating airflow or a failing blower motor can be costly. Regular filter replacement and vent cleaning preserve efficiency; lubrication and alignment may extend blower life. However, if the blower shows electrical faults, bearings are worn beyond repair, or airflow loss is caused by structural duct damage, replacement of the blower or sections of ducting may be more cost-effective than piecemeal repairs that don’t resolve the underlying airflow issues.

When combustion, ignition, and flue issues mean replace

Components involved in combustion and ignition directly affect safety. Persistent ignition failure, incomplete combustion, soot buildup, cracked heat exchangers, or a damaged flue increase carbon monoxide and fire risk. These are situations where replacement is often necessary rather than repair. If diagnostics reveal recurring combustion instability or flue leaks that cannot be reliably sealed, replacing the compromised components—or the entire appliance—may be the prudent choice for safety and code compliance.

Can diagnostics, calibration, and lubrication restore performance?

Many systems respond well to thorough diagnostics, careful calibration, and preventive lubrication. Routine maintenance that includes sensor testing, calibration of controls, condensate drain inspection, and lubrication of moving parts can restore efficiency and extend life. Use diagnostics to distinguish intermittent electrical faults from mechanical wear: if diagnostics repeatedly return different fault codes or calibration cannot stabilize system operation, replacement should be considered.

How do sensors, zoning, scheduling, and condensate influence decisions?

Modern systems rely on sensors, zoning dampers, and scheduling logic to deliver efficient comfort. Failing sensors, stuck dampers, or condensate drain issues can lead to uneven heating and frequent service calls. When upgrades to zoning or scheduling capabilities are desired, it may make sense to replace older control modules or sensors to integrate efficiently. Persistent condensate problems that lead to corrosion or electrical damage also increase the case for component replacement rather than repeated cleanings.

Conclusion Replacement outweighs repair when inspections and diagnostics show chronic failures, safety risks from combustion or flue defects, discontinued parts, or when repairs no longer deliver acceptable efficiency and reliability. Consider the age of the equipment, expected remaining life, upgrade needs for sensors and controls, and the cumulative cost of repeated service. Prioritizing safety, measurable efficiency gains, and predictable operation helps determine whether repair or replacement best serves long‑term needs.