Worldwide pay factors and hiring trends for production roles

This article summarizes global factors that influence pay and hiring trends for production roles. It highlights skills, workplace practices, and market forces affecting assembly and manufacturing positions, offering a concise preview of the topics covered in the full article.

Pay and hiring trends for production roles reflect a mix of technical skills, operational demands, and regulatory environments across regions. Employers weigh competencies such as assembly technique, familiarity with manufacturing equipment, and the ability to follow blueprints and inspection protocols. At the same time, local labor markets, collective bargaining, automation adoption, and economic cycles shape demand for workers and the types of compensation and benefits offered. This article outlines the key factors that influence pay and hiring, focusing on practical elements that candidates and workforce planners commonly encounter.

What assembly and manufacturing skills matter?

Employers increasingly prioritize hands-on capabilities that reduce onboarding time and support steady productivity. Core competencies include precise assembly following blueprints, basic electronics knowledge, soldering and wiring skills for certain product lines, and the ability to perform quality inspections. Candidates who can troubleshoot intermittent faults on the line, interpret technical drawings, and adapt to multiple product variants are more likely to be considered for stable roles. These practical skills interact with experience and demonstrated productivity: reliable output and low defect rates often translate into more favorable hiring decisions, even when formal credentials are limited.

How do safety and ergonomics affect pay?

Workplaces that emphasize safety and ergonomics influence both hiring practices and compensation structures. Employers in regulated industries may require specific training or certifications related to workplace safety and ergonomics assessments, which can become prerequisites for certain roles. Jobs that involve repetitive motion, heavy lifting, or hazardous materials typically prompt investments in ergonomic improvements and additional safety training. While safety measures themselves do not guarantee higher pay, positions demanding hazardous-material handling certifications, or those located in tightly regulated jurisdictions, can carry wage premiums or enhanced benefits to reflect the added responsibilities and compliance costs.

How do training and certification influence hiring?

Structured training programs and industry certifications help standardize skill levels and reduce recruitment risk. Employers often prefer candidates with certifications that verify competence in areas such as soldering standards, electronics assembly, or quality inspection methodologies. On-the-job training programs, apprenticeships, and partnerships with vocational schools can broaden the applicant pool and influence hiring patterns by creating pipelines of trained workers. Organizations investing in upskilling may offer clearer progression paths and skills-based pay adjustments, while companies with limited training resources may favor applicants who already hold applicable credentials.

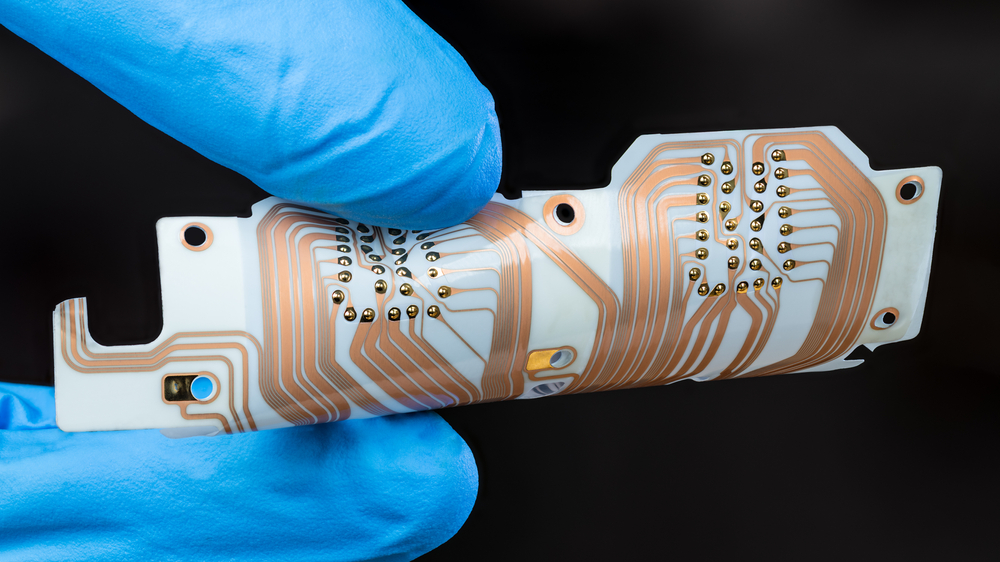

How do electronics, soldering, and wiring shape roles?

When production involves electronics, hiring criteria shift toward fine-motor skills, attention to detail, and familiarity with components and testing procedures. Soldering and wiring work often require specialized tools, static-sensitive handling, and inspection protocols to ensure reliability. In many facilities, personnel performing these tasks must adhere to stricter quality controls and inspection checklists, and they are typically evaluated on first-pass yields and defect rates. These technical demands can affect hiring by narrowing candidate pools and prompting employers to seek workers with targeted experience or willingness to undergo certification and continuous training.

How do inspection, quality, and productivity affect hiring trends?

Quality systems and inspection regimes create measurable performance expectations that influence hiring and retention. Roles tied closely to inspection and quality assurance may require familiarity with inspection equipment, defect classification, and documentation practices. Productivity metrics—such as cycle times, throughput, and yield—play a role in workforce planning: during periods of high demand, employers may hire temporary staff or adjust shift patterns; when automation improves throughput, hiring may shift to roles focused on machine oversight and troubleshooting. A balanced approach to hiring usually values candidates who can meet quality standards while contributing to steady productivity.

How do shifts and troubleshooting impact employment patterns?

Shift work and troubleshooting responsibilities shape both the kinds of applicants attracted to production roles and employer compensation policies. Night or rotating shifts can affect recruitment and retention, prompting adjustments in scheduling practices, shift differentials, or flexible work options in some firms. Troubleshooting skills—rapid diagnosis of mechanical, electrical, or process issues—are highly valued because they reduce downtime and maintain production continuity. Employers may prioritize multiskilled candidates who can move between assembly, inspection, and maintenance-support tasks, which can influence how roles are advertised and how internal progression is structured.

Conclusion

Pay and hiring trends for production roles are driven by a combination of technical skill requirements, workplace safety and ergonomics, training and certification availability, and operational metrics like quality and productivity. Regional labor markets and levels of automation also shape demand and role definitions. Understanding these factors helps clarify why employers prioritize certain competencies and how workforce strategies evolve as manufacturing practices change.