3D Printing Guide: Modern Additive Manufacturing Explained

Explore how 3D printing and additive manufacturing are reshaping production — from rapid prototyping to bespoke parts. This guide covers materials like PLA, ABS, PETG, and TPU, home workshop setup, essential software (CAD and slicers), and computer specs to get started. Learn practical tips for hobbyists and professionals alike and discover why industries such as aerospace, automotive, and healthcare rely on 3D printing for precision and customization.

How 3D Printing Is Changing Manufacturing

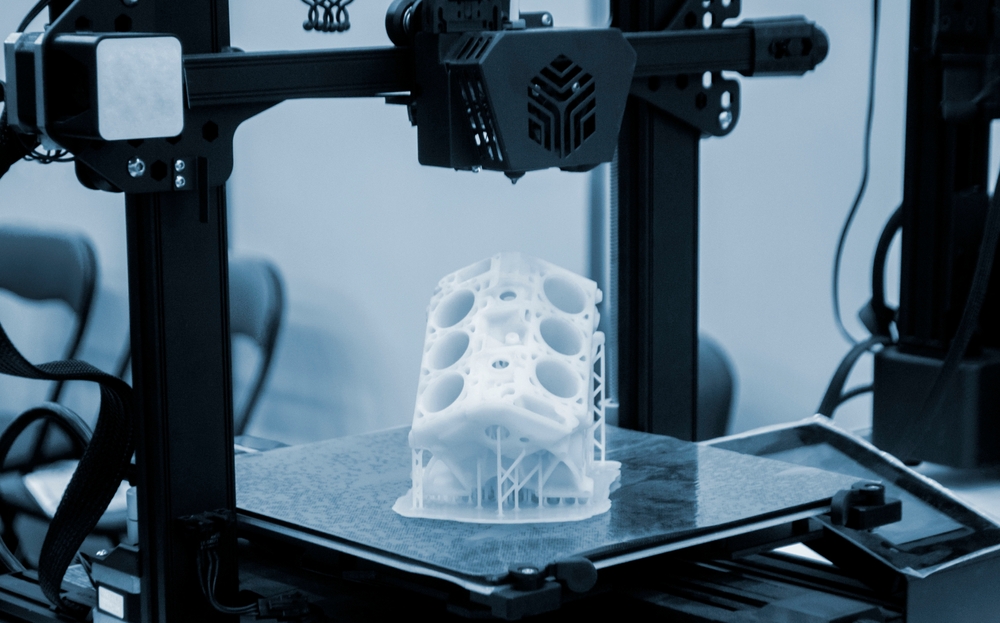

Additive manufacturing, commonly called 3D printing, has altered the manufacturing landscape by enabling parts to be built layer by layer from digital models. This method shortens development cycles, cuts tooling costs, and allows designers to produce shapes that would be difficult or impossible with subtractive methods. Companies across sectors — especially aerospace, automotive, and medical devices — leverage 3D printing for customized components, lightweight structures, and precision parts that meet strict performance requirements.

Beyond large-scale production, the technology accelerates iterative design. Engineers can print prototypes overnight, test fit and function, revise CAD models, and run another print the next day. That speed-to-feedback loop reduces time-to-market and lowers the expense tied to early-stage testing.

Building a Home 3D Printing Workspace

Setting up a reliable home printing area involves planning for space, equipment, and safety. Start by choosing a well-ventilated location with a stable work surface and enough room for filament spools, tools, and post-processing tasks. Essential items include the printer, a computer for design and slicing, filament storage, basic hand tools (flush cutters, scrapers, tweezers), and a fire-safe power setup.

Many beginners opt for entry-level fused deposition modeling (FDM) printers because they are affordable and straightforward to operate. As skills and demands grow, hobbyists often upgrade to printers with larger build volumes, dual extrusion, or higher-temperature capabilities for advanced materials.

Safety and maintenance are important: ensure good ventilation or an enclosure with filtration when printing certain plastics, keep the printer clean and well-calibrated, and store filaments in sealed containers with desiccant to prevent moisture absorption.

Typical Uses and Material Choices

3D printers serve a wide variety of uses: creating replacement parts, producing jigs and fixtures for workshops, manufacturing functional prototypes, and crafting artistic pieces and customized consumer goods. Material choice depends on the intended use — strength, flexibility, temperature resistance, and finish quality all influence which filament is best.

| Material Type | Common Uses | Average Cost Range |

|---|---|---|

| PLA | Hobby projects, visual prototypes | $20-30/kg |

| ABS | Functional parts, automotive components | $25-35/kg |

| PETG | Food-contact containers (with care), outdoor parts | $30-40/kg |

| TPU | Flexible items, phone cases, seals | $35-45/kg |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

When choosing a material, consider print temperature, bed adhesion needs, post-processing options, and any health or food-safety implications. For example, PLA prints easily and yields a good surface finish, while ABS offers greater toughness and heat resistance but can warp and emit stronger odors during printing. PETG is a middle ground with chemical resistance and good layer adhesion, and TPU provides elasticity for wearables and seals.

Computer and Software Essentials

A capable computer and the right software pipeline are crucial for turning digital ideas into printed objects. Minimum and recommended specifications help ensure smooth modeling and slicing:

- Processor: modern multi-core CPU (Intel i5/Ryzen 5 or better recommended)

- RAM: at least 8GB; 16GB+ preferred for large assemblies or high-poly models

- Graphics: a dedicated GPU helps with complex CAD rendering, though many CAD packages run on integrated graphics for basic tasks

- Storage: SSD for faster file access and program performance

Software components include CAD tools for designing parts and slicers that convert 3D models into g-code the printer can use. Popular CAD options range from beginner-friendly Tinkercad to professional-grade Fusion 360 and Blender. Widely used slicing programs include Cura, PrusaSlicer, and Simplify3D. Each slicer offers profile settings for layer height, infill, support structures, and print speeds — mastering these settings is key to consistent results.

Best Practices and Tips for Success

Start with simple designs to learn calibration, bed leveling, and filament behavior. Keep spare parts and maintenance tools on hand, and document printer settings that produce good results for different materials. For functional components, consider design strategies like adding fillets, orienting parts to optimize strength along load paths, and tuning infill percentage to balance weight and durability.

Post-processing techniques such as sanding, priming, vapor smoothing (for ABS), and painting can improve aesthetics and fit. For critical applications — medical devices or safety-related parts — follow regulatory guidelines and validate printed components through testing.

The Future of Additive Manufacturing

3D printing continues to evolve: new materials, hybrid manufacturing techniques, and improved printer reliability make additive processes more viable for end-use production. As suppliers expand filament options and printers add higher resolution and multi-material capabilities, both makers and manufacturers will find more opportunities to integrate 3D printing into production workflows. Whether you’re a hobbyist building personalized projects or a business optimizing supply chains, additive manufacturing offers flexible, creative, and efficient ways to translate digital designs into physical products.