3D Printing: A Revolutionary Technology Transforming Manufacturing and Home Production

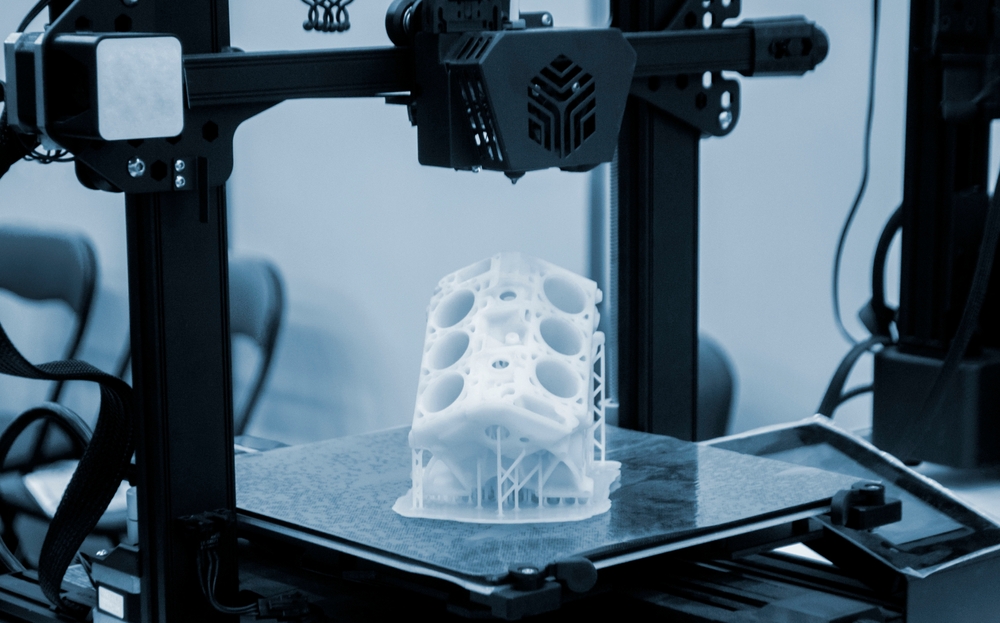

3D printing technology has revolutionized how we think about manufacturing and creation, enabling both industries and individuals to transform digital designs into physical objects. This additive manufacturing process builds objects layer by layer, offering unprecedented flexibility in prototyping, customization, and small-scale production. From rapid prototyping in industries to creative projects at home, 3D printing is reshaping our approach to making things.

The Rise of Home 3D Printing

Home 3D printers have become increasingly accessible, allowing enthusiasts to create everything from toys to replacement parts. These desktop machines typically use plastic filaments and connect to home computers via USB or Wi-Fi. Modern printers feature user-friendly interfaces, automated bed leveling, and various quality-of-life improvements that make 3D printing more approachable for beginners.

Manufacturing Applications and Industry Impact

In manufacturing, 3D printing has become an essential tool for prototyping, custom parts production, and small-batch manufacturing. Industries including aerospace, automotive, and medical devices leverage this technology to reduce costs, accelerate development cycles, and create complex geometries impossible with traditional manufacturing methods. The technology enables on-demand production, reducing inventory needs and shipping costs.

Computer Software and Design Tools

The 3D printing process relies heavily on computer software for design and printer control. Popular CAD programs like Fusion 360, TinkerCAD, and Blender allow users to create or modify 3D models. Slicer software then converts these designs into printer instructions, controlling parameters like layer height, infill density, and support structures.

Current Market Options and Pricing

The 3D printer market offers options for various skill levels and applications. Here’s a comparison of popular consumer models:

| Printer Model | Type | Build Volume | Price Range |

|---|---|---|---|

| Prusa i3 MK3S+ | FDM | 250x210x210mm | $749-999 |

| Creality Ender 3 V2 | FDM | 220x220x250mm | $279-329 |

| Elegoo Mars 2 Pro | Resin | 129x80x160mm | $200-250 |

| Flashforge Creator Pro | FDM | 225x145x150mm | $599-699 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Maintenance and Operating Considerations

Successful 3D printing requires regular maintenance and understanding of various operating parameters. Key considerations include proper bed leveling, temperature control, and material storage. Users should factor in ongoing costs such as filament replacement, potential part upgrades, and occasional repairs. Regular calibration and cleaning help ensure consistent print quality and extend the printer’s lifespan.

The future of 3D printing continues to expand with new materials, improved technologies, and broader applications. From hobbyist creators to industrial manufacturers, this technology provides unprecedented capabilities for turning digital designs into physical reality. As the technology matures, we can expect to see even more innovative uses and improvements in accessibility, speed, and precision.