3D Printing Revolution: Understanding Modern Manufacturing at Home

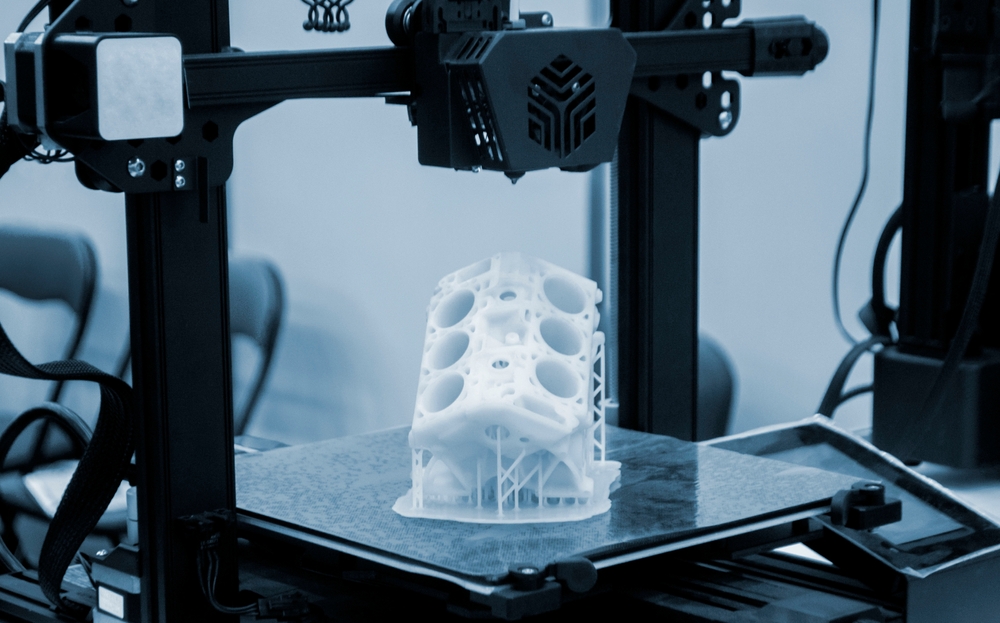

3D printing technology has transformed from an industrial novelty into a powerful tool that's revolutionizing manufacturing, prototyping, and creative expression. This innovative technology allows users to create three-dimensional objects from digital designs, bringing professional manufacturing capabilities into homes and small businesses. The process has become increasingly accessible, enabling everyone from hobbyists to entrepreneurs to produce custom items with remarkable precision.

The Impact of 3D Printing on Home Manufacturing

The accessibility of 3D printers has democratized manufacturing, allowing individuals to produce items from the comfort of their homes. From replacement parts to custom decorative pieces, home 3D printing enables users to create objects that would otherwise be expensive or impossible to obtain. This technology has particularly benefited makers, artists, and DIY enthusiasts who can now prototype and produce their designs without industrial equipment.

Computer Requirements for 3D Printing

To effectively operate a 3D printer, users need a computer system capable of running specialized design software and processing complex 3D models. Most modern computers with at least 8GB of RAM, a dedicated graphics card, and a multi-core processor can handle basic 3D printing tasks. The computer must also run slicing software, which converts 3D models into printer-readable instructions.

Comparing Popular 3D Printer Options

When selecting a 3D printer, various factors influence the decision. Here’s a comparison of current market options:

| Printer Model | Type | Build Volume | Price Range |

|---|---|---|---|

| Prusa i3 MK3S+ | FDM | 250 x 210 x 210 mm | $749-999 |

| Elegoo Mars 2 Pro | Resin | 129 x 80 x 160 mm | $200-300 |

| Creality Ender 3 V2 | FDM | 220 x 220 x 250 mm | $200-300 |

| Flashforge Creator Pro 2 | FDM | 200 x 148 x 150 mm | $600-800 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Future Developments in 3D Printing Technology

The future of 3D printing continues to evolve with improvements in printing speed, material options, and precision. Advances in technology are making printers more reliable and user-friendly while expanding their capabilities. New materials are being developed regularly, including specialized composites and biodegradable options, opening up possibilities for more sustainable and innovative applications in home manufacturing.

3D printing represents a significant shift in how we think about manufacturing and creation. As the technology becomes more refined and accessible, its impact on home production, custom manufacturing, and creative expression will continue to grow. Whether for practical applications or artistic endeavors, 3D printing provides unprecedented opportunities for individuals to bring their ideas to life.