The Revolutionary World of 3D Printing: From Industrial Manufacturing to Home Creation

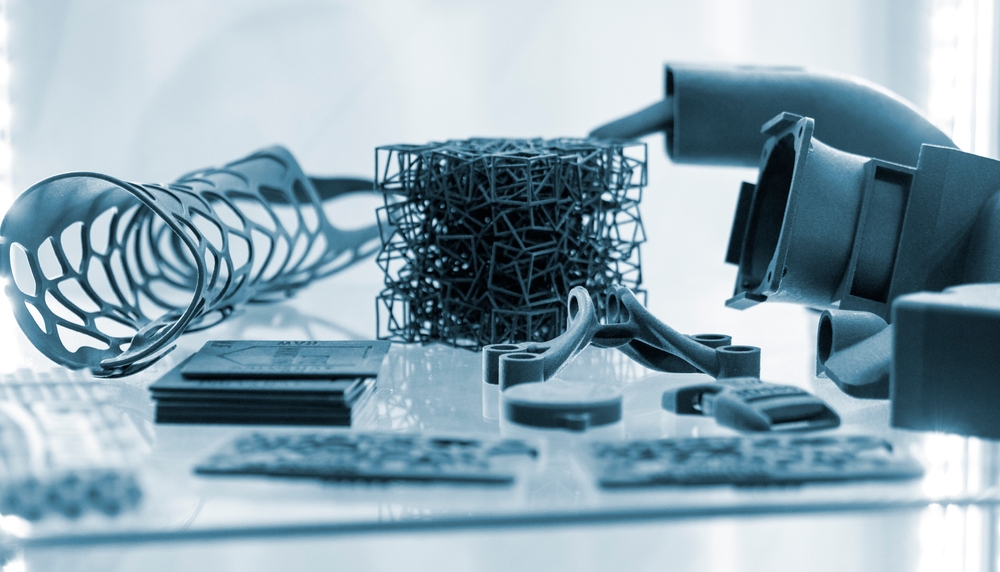

Three-dimensional printing has transformed from a niche industrial technology into a versatile tool that's reshaping how we create, manufacture, and innovate. This groundbreaking technology allows users to transform digital designs into physical objects, layer by layer, opening up unprecedented possibilities for both professional manufacturing and home-based creation.

The Evolution of Home 3D Printing

What was once confined to industrial settings has now found its way into homes and small businesses. Modern home 3D printers are more compact, user-friendly, and affordable than ever before. These devices connect to home computers through USB or Wi-Fi, allowing users to print everything from replacement parts to custom decorative items. The accessibility of free design software and online communities has made it easier for beginners to start creating.

Applications in Manufacturing

In the manufacturing sector, 3D printing has revolutionized prototyping and production processes. Companies use industrial-grade printers to create complex components, reduce waste, and decrease production time. The technology enables rapid prototyping, allowing manufacturers to test and refine designs quickly before moving to mass production. This capability has proven particularly valuable in aerospace, automotive, and medical device manufacturing.

Getting Started with Home 3D Printing

For those interested in bringing this technology home, several key components are necessary. A reliable computer with adequate processing power is essential for running 3D modeling software. Entry-level printers typically connect via USB, while more advanced models offer wireless connectivity. Users also need to familiarize themselves with slicing software, which converts 3D models into printer-ready instructions.

Current Market Options and Pricing

| Printer Type | Target User | Average Price Range |

|---|---|---|

| Entry-Level FDM | Home Hobbyist | $200 - $500 |

| Mid-Range FDM | Enthusiast | $500 - $1,500 |

| Professional FDM | Small Business | $1,500 - $5,000 |

| Resin (SLA/DLP) | Detail-Oriented | $300 - $3,000 |

| Industrial | Manufacturing | $10,000+ |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Future Implications of 3D Printing

The technology continues to evolve, with innovations in materials, speed, and precision constantly emerging. As 3D printers become more sophisticated and accessible, their impact on manufacturing, education, and home creation will likely expand. The ability to produce custom items on demand could reduce waste, decrease shipping needs, and democratize manufacturing capabilities for individuals and small businesses.

The convergence of advanced manufacturing technology with home computing has made 3D printing a powerful tool for innovation and creativity. Whether used for professional manufacturing or personal projects, 3D printers represent a significant step forward in how we conceive, design, and create physical objects in the modern world.