Laser Cleaning: Revolutionizing Industrial Machinery Maintenance

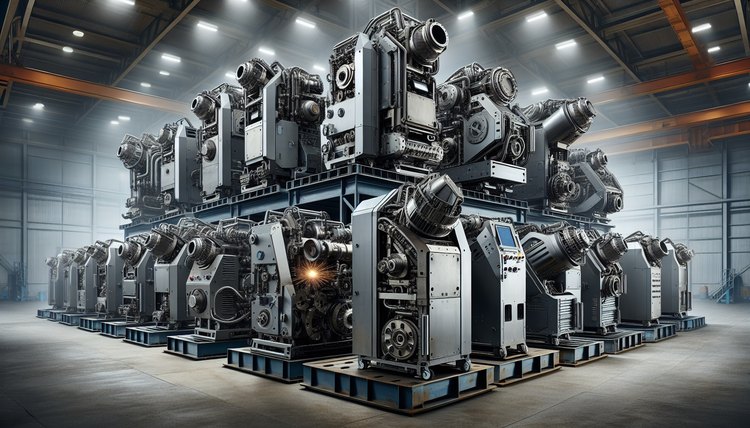

Laser cleaning technology is rapidly transforming the landscape of industrial machinery maintenance. This innovative approach offers a precise, efficient, and environmentally friendly alternative to traditional cleaning methods. As industries seek more effective ways to maintain their equipment, laser cleaning has emerged as a powerful tool in the modern maintenance arsenal.

How does laser cleaning benefit industrial machinery?

Industrial machinery often operates in harsh environments, accumulating layers of grime, oxidation, and other contaminants over time. Laser cleaning offers several advantages in maintaining these machines:

-

Precision: Lasers can be finely tuned to remove specific contaminants without affecting the base material.

-

Efficiency: The process is faster than many traditional cleaning methods, reducing downtime.

-

Environmentally friendly: Laser cleaning eliminates the need for chemical solvents or abrasive materials, reducing waste and environmental impact.

-

Versatility: It can be used on a wide range of materials and surfaces, including metals, plastics, and composites.

-

Safety: The non-contact nature of laser cleaning reduces the risk of injury to operators compared to manual cleaning methods.

What types of laser cleaning machines are available?

Laser cleaning machines come in various configurations to suit different industrial needs:

-

Handheld laser cleaning tools: These portable devices are ideal for spot cleaning and hard-to-reach areas.

-

Automated laser cleaning systems: Designed for large-scale operations, these machines can clean large surfaces or multiple parts simultaneously.

-

Robotic laser cleaning systems: These integrate laser cleaning technology with robotic arms for complex geometries or hazardous environments.

-

Pulsed laser cleaning machines: Utilizing short, high-energy pulses, these are effective for removing thin layers of contaminants without damaging sensitive substrates.

How to choose the right laser cleaning tool for industrial applications?

Selecting the appropriate laser cleaning tool depends on several factors:

-

Material composition: Different materials may require specific laser wavelengths for optimal cleaning.

-

Contaminant type: The nature of the contaminants (e.g., rust, paint, oil) influences the laser power and pulse duration needed.

-

Surface area and geometry: Large, flat surfaces may benefit from automated systems, while complex shapes might require handheld or robotic solutions.

-

Production volume: High-volume cleaning needs may justify investment in more advanced, automated systems.

-

Environmental considerations: Some industries may require enclosed systems with fume extraction for safety and regulatory compliance.

What are the latest advancements in laser cleaning technology?

Laser cleaning technology continues to evolve, with recent advancements including:

-

Improved laser sources: More efficient and powerful lasers are expanding the range of materials and contaminants that can be effectively cleaned.

-

Artificial intelligence integration: AI-powered systems can optimize cleaning parameters in real-time, improving efficiency and results.

-

Compact designs: Smaller, more portable laser cleaning tools are making the technology accessible to a broader range of industries and applications.

-

Multi-wavelength systems: These versatile machines can switch between different laser wavelengths to tackle various cleaning tasks with a single tool.

-

Enhanced safety features: Advanced sensor systems and protective enclosures are making laser cleaning safer for operators and the environment.

| Laser Cleaning Machine | Provider | Key Features | Cost Estimation |

|---|---|---|---|

| CleanLase 1000 | IPG Photonics | High-power, pulsed fiber laser, portable design | $50,000 - $80,000 |

| P-Laser CL1000 | P-Laser | Compact, air-cooled system, user-friendly interface | $40,000 - $60,000 |

| CleanTech Laser | MECCO | Automated system, suitable for large surfaces | $100,000 - $150,000 |

| LaserClean | Laser Photonics | Handheld and automated options, multiple power levels | $30,000 - $120,000 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

As industrial machinery becomes more sophisticated, the demand for advanced cleaning solutions continues to grow. Laser cleaning technology offers a compelling answer to this need, providing a powerful, precise, and environmentally friendly method for maintaining critical equipment. From handheld tools to fully automated systems, laser cleaning machines are revolutionizing industrial maintenance practices across various sectors. As the technology advances, we can expect even more efficient and versatile solutions to emerge, further cementing laser cleaning’s place in the industrial toolbox of the future.