Revolutionizing Industrial Cleaning: The Power of Laser Technology

Laser cleaning technology is transforming the industrial machinery landscape, offering a cutting-edge solution for maintaining and restoring equipment. This innovative approach uses high-powered lasers to remove contaminants, rust, and coatings from various surfaces without causing damage to the underlying material. As industries seek more efficient and environmentally friendly cleaning methods, laser technology has emerged as a game-changer in the field of industrial maintenance.

The key to laser cleaning’s effectiveness lies in its ability to differentiate between the target contaminant and the underlying surface. By adjusting the laser’s wavelength, pulse duration, and energy density, operators can fine-tune the cleaning process for specific applications. This level of control makes laser cleaning suitable for a wide range of materials, including metals, plastics, and even delicate surfaces like historical artifacts.

What are the advantages of laser cleaning machines?

Laser cleaning machines offer several significant advantages over traditional cleaning methods:

-

Precision: Laser cleaning allows for highly targeted removal of contaminants, minimizing the risk of damage to the underlying surface.

-

Environmentally friendly: The process doesn’t require chemicals or abrasives, reducing waste and environmental impact.

-

Cost-effective: While initial investment may be higher, laser cleaning can be more cost-effective in the long run due to reduced consumables and labor costs.

-

Versatility: Laser cleaning machines can be used on a wide variety of materials and contaminants, making them suitable for diverse industrial applications.

-

Safety: The non-contact nature of laser cleaning reduces the risk of injury to operators compared to some traditional cleaning methods.

What industries benefit from laser cleaning technology?

Laser cleaning technology has found applications across numerous industries:

-

Automotive: Removing paint, rust, and coatings from car bodies and parts.

-

Aerospace: Cleaning and prepping aircraft components for inspection and maintenance.

-

Electronics: Precise cleaning of circuit boards and electronic components.

-

Heritage conservation: Gentle restoration of historical artifacts and buildings.

-

Manufacturing: Cleaning molds, tools, and production equipment.

-

Energy: Maintenance of power generation equipment and pipelines.

The versatility of laser cleaning makes it an invaluable tool in industries where precision cleaning is crucial for quality, safety, and efficiency.

How to choose the right laser cleaning machine?

Selecting the appropriate laser cleaning machine depends on several factors:

-

Material type: Different materials may require specific laser wavelengths for optimal cleaning.

-

Contaminant type: The nature of the dirt or coating to be removed influences the choice of laser parameters.

-

Scale of operation: Consider the size of the objects to be cleaned and the required cleaning speed.

-

Portability: Some applications may benefit from mobile laser cleaning systems for on-site work.

-

Safety features: Look for machines with proper safety mechanisms and certifications.

-

Support and training: Consider the level of technical support and operator training provided by the manufacturer.

What are the latest advancements in laser cleaning technology?

Recent developments in laser cleaning technology have focused on improving efficiency, versatility, and ease of use:

-

Fiber laser integration: Fiber lasers offer improved beam quality and energy efficiency, enhancing cleaning performance.

-

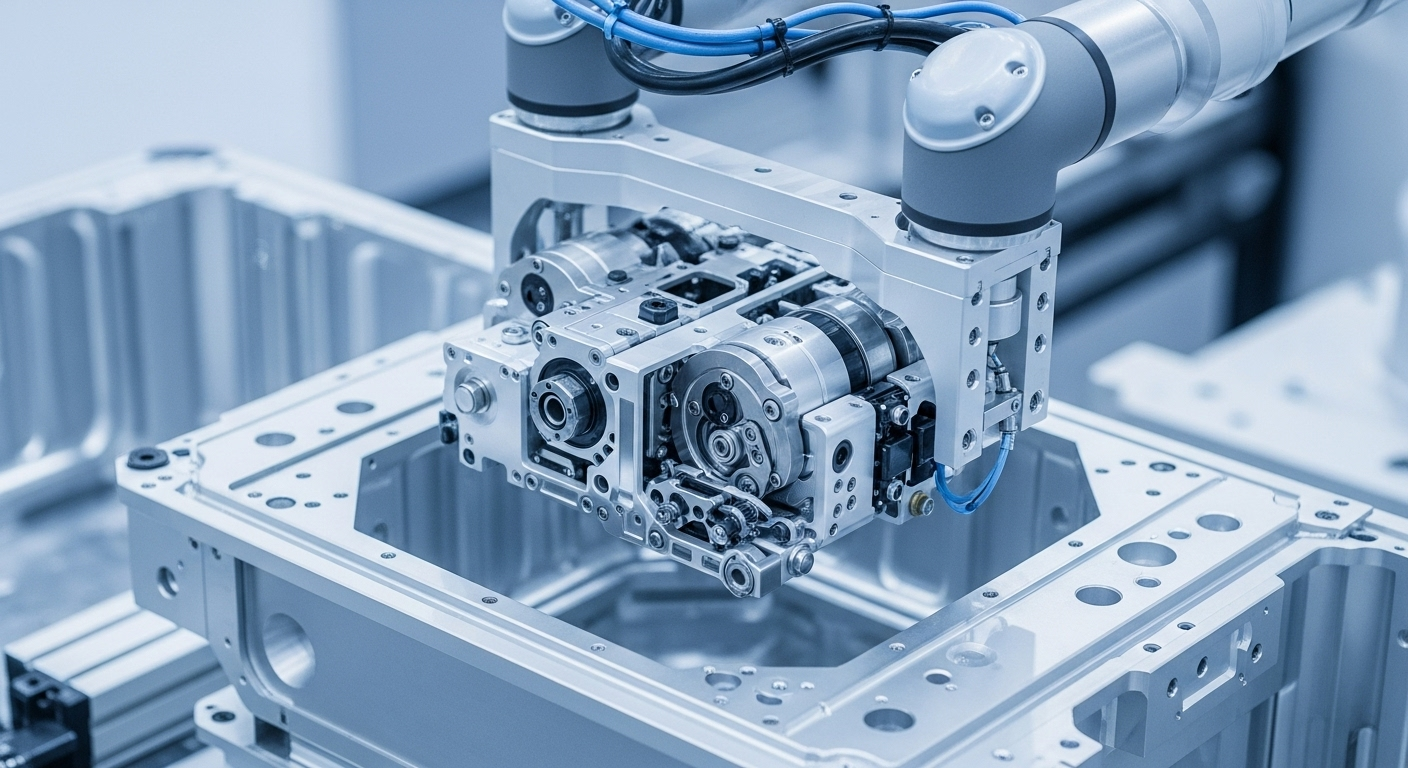

Automated systems: Integration with robotics and AI for more precise and efficient cleaning processes.

-

Compact designs: Development of smaller, more portable laser cleaning tools for field applications.

-

Multi-wavelength systems: Machines capable of operating at different wavelengths to tackle a wider range of materials and contaminants.

-

Improved user interfaces: More intuitive controls and real-time monitoring systems for easier operation.

These advancements are making laser cleaning technology more accessible and effective across various industrial applications.

What are the cost considerations for laser cleaning machines?

When considering laser cleaning machines, it’s important to understand the cost implications:

-

Initial investment: Laser cleaning machines typically have a higher upfront cost compared to traditional cleaning methods.

-

Operating costs: Lower ongoing expenses due to reduced consumables and labor requirements.

-

Maintenance: Regular servicing and potential component replacements should be factored into long-term costs.

-

Training: Investment in operator training is crucial for safe and effective use of the technology.

-

Energy consumption: While generally efficient, high-powered laser systems may have significant energy requirements.

| Laser Cleaning Machine Type | Approximate Cost Range | Key Features |

|---|---|---|

| Entry-level handheld | $10,000 - $30,000 | Portable, suitable for small-scale applications |

| Mid-range industrial | $50,000 - $150,000 | Higher power, faster cleaning, diverse material capability |

| High-end automated system | $200,000 - $500,000+ | Integrated robotics, multi-axis control, high-volume production |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Laser cleaning technology represents a significant advancement in industrial cleaning and maintenance. Its precision, environmental friendliness, and versatility make it an attractive option for many industries. As the technology continues to evolve, we can expect to see even more innovative applications and improvements in efficiency. For businesses considering the adoption of laser cleaning machines, careful evaluation of needs, costs, and long-term benefits is essential to make an informed decision.