The Mechanics of Industrial Material Shaping

Molding machines are fundamental to modern industrial production, enabling the transformation of raw materials into intricate and functional components across various sectors. These sophisticated pieces of equipment are central to the manufacturing process, allowing for the precise shaping and forming of materials like plastics, metals, and composites. Understanding their operation and diverse applications provides insight into the backbone of contemporary fabrication.

What are Molding Machines and Their Role in Manufacturing?

Molding machines are specialized industrial equipment designed to create objects by shaping liquid or pliable raw material using a rigid frame called a mold. This process is critical in manufacturing for producing a vast array of industrial products, from automotive parts and consumer goods to medical devices and construction materials. The core function of these machines is to facilitate the production of items with specific geometries, ensuring consistency and accuracy across large volumes. They are indispensable for achieving high levels of detail and repeatable quality, driving efficiency in fabrication lines globally.

Key Types of Molding Processes and Their Applications

The world of molding encompasses several distinct processes, each suited to different material types and product requirements. Injection molding, for instance, is widely used for plastics, where molten material is injected into a mold cavity and then cooled to solidify. Blow molding is another technique, primarily for hollow plastic objects like bottles, involving inflating a heated plastic parison inside a mold. Compression molding is often applied to thermosetting plastics and composites, where material is placed in an open, heated mold cavity and then compressed. Each method excels at shaping and forming materials to meet diverse design specifications.

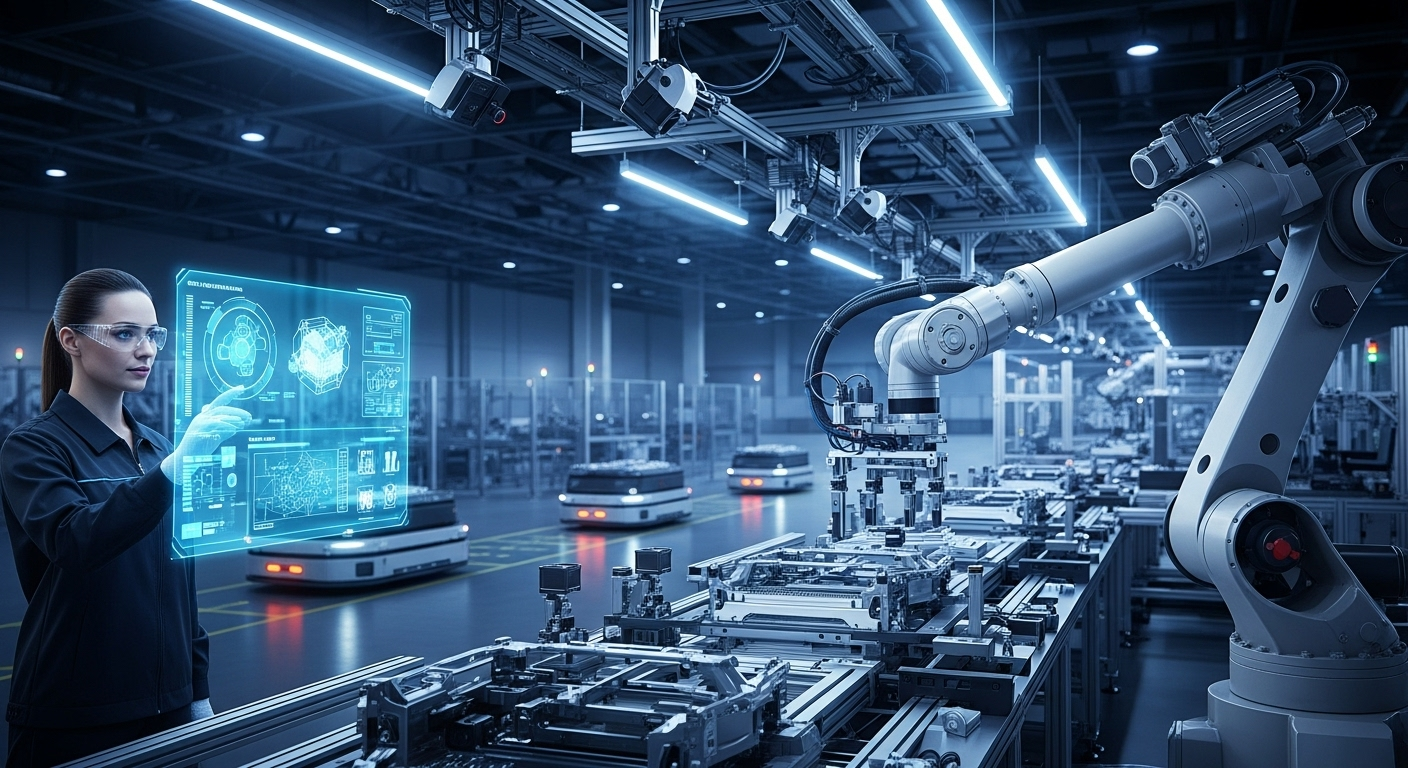

How Automation and Engineering Enhance Molding Efficiency

Modern molding operations heavily rely on automation to optimize production cycles and reduce labor costs. Robotic systems are frequently integrated for material handling, part removal, and quality inspection, which significantly boosts efficiency. Advanced engineering principles are applied in the design of both the machines and the molds themselves, ensuring precise control over parameters such as temperature, pressure, and cycle time. This integration of technology allows for continuous operation, minimal human intervention, and consistent output quality, making manufacturing processes more reliable and cost-effective.

Understanding the Components and Tooling in Molding Systems

Effective molding relies on a complex interplay of machinery and equipment components. Key elements include the clamping unit, which holds the mold halves together, and the injection unit, which melts and injects the material. The mold itself, often referred to as tooling, is a precision-engineered device that defines the final shape of the product. These molds are typically made from hardened steel or aluminum and can be incredibly intricate, featuring multiple cavities, cooling channels, and ejector pins. The proper design and maintenance of these systems are paramount for long-term operational success and product quality.

Innovation and Future Trends in Molding Technology

The field of molding technology continues to evolve through constant innovation. Advances include the development of more energy-efficient machines, the integration of smart sensors for real-time process monitoring, and the use of advanced materials that offer enhanced performance and sustainability. Additive manufacturing, or 3D printing, is also influencing tooling design by enabling the rapid production of complex mold inserts. These developments contribute to faster prototyping, reduced waste, and the ability to create increasingly complex and customized components, pushing the boundaries of what is achievable in industrial shaping.

| Provider Name | Services Offered | Key Features/Benefits |

|---|---|---|

| Engel Austria | Injection molding machines, automation solutions | High-precision, energy-efficient, integrated systems |

| KraussMaffei | Injection molding, extrusion, reaction process tech | Broad portfolio, digitalization, custom solutions |

| Arburg | Injection molding machines, additive manufacturing | Versatile, compact, electric and hydraulic options |

| Husky Injection Molding | Injection molding systems, hot runners, auxiliaries | Specializes in PET preform and closure molding, global support |

| Milacron | Injection, blow, and extrusion molding machines | Robust, diverse range, aftermarket services |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

In conclusion, molding machines are central to modern industrial production, offering diverse methods for shaping and forming various materials. The continuous integration of automation, advanced engineering, and material science innovation ensures their ongoing relevance and capability to meet ever-evolving manufacturing demands. These systems, with their intricate components and specialized tooling, are critical enablers of efficiency and precision in fabrication across numerous sectors worldwide.