Career Progression Steps from Operator to Maintenance Technician

This article explains practical, step-by-step approaches for operators who want to move into maintenance technician roles within manufacturing environments. It highlights transferable skills, structured training, common workplace practices, and how to align hands-on experience with technical responsibilities across production settings.

Operators who aim to become maintenance technicians should focus on building technical knowledge, documenting hands-on experience, and following structured training pathways. In many manufacturing environments, operators already touch equipment, perform basic troubleshooting, and follow quality and safety processes; the transition to a maintenance role requires expanding that foundation into systematic diagnostics, preventative work, and formal calibration and repair practices. This article lays out concrete progression steps and workplace considerations that apply across production contexts, from electronics assembly to heavier mechanical lines.

How does manufacturing production experience help?

Experience in manufacturing and production provides a practical baseline for maintenance work. Operators who understand production flow, cycle times, and common failure modes can diagnose problems faster because they know how machines integrate into the line. Familiarity with production documentation, standard operating procedures, and changeover steps helps when performing preventive maintenance or participating in root-cause analysis. Employers often value operators who can bridge the gap between running equipment and maintaining it: this includes contributing to continuous improvement initiatives and communicating effectively with engineering and quality teams.

What electronics and soldering skills are needed?

Maintenance on electronics-heavy equipment benefits from basic electronics knowledge and soldering competency. Learning to read schematics, identify common components (resistors, capacitors, diodes), and perform safe soldering and desoldering allows technicians to repair control boards and connectors. Safe work practices—ESD controls, proper soldering iron techniques, and inspection of solder joints—are important. These skills are often developed through hands-on practice, vocational courses, or mentorship programs and should be paired with documentation habits that track repairs and part replacements.

How do inspection, fixtures, and calibration relate?

Inspection routines, fixtures, and calibration form the backbone of reliable maintenance. Routine inspections help identify wear, misalignment, or loose fasteners before failures occur. Knowledge of fixtures—how jigs and tooling are mounted and adjusted—helps technicians restore correct part handling and tolerances. Calibration skills are essential for devices that control critical parameters; understanding calibration intervals, traceability, and basic metrology lets a technician verify sensors and gauges meet production requirements. Documentation of inspection findings and calibration records supports quality and regulatory compliance.

How does ergonomics and handtools affect work?

Ergonomics and correct use of handtools influence both productivity and safety in maintenance tasks. Technicians should be trained to use torque wrenches, pliers, screwdrivers, and specialty handtools safely and to select the right tool for the task to avoid damage. Ergonomic considerations—proper lifting techniques, workstation setup, and tools that reduce repetitive strain—lower injury risk and improve consistency of repairs. Incorporating ergonomics into daily routines also supports longer-term career sustainability by reducing musculoskeletal stress that can arise from repetitive maintenance work.

What training and onboarding steps are typical?

Structured training and onboarding accelerate the move from operator to technician. Common steps include shadowing experienced technicians, attending vendor training for specific equipment, and completing classroom or online modules covering electrical safety, lockout/tagout, and preventive maintenance planning. Cross-training in related areas—PLC basics, pneumatics, and hydraulics—broadens capability. Onboarding should include access to maintenance manuals, parts lists, and a mentor who reviews initial repairs. Good training programs combine supervised hands-on tasks with documented competency checks and refresher modules.

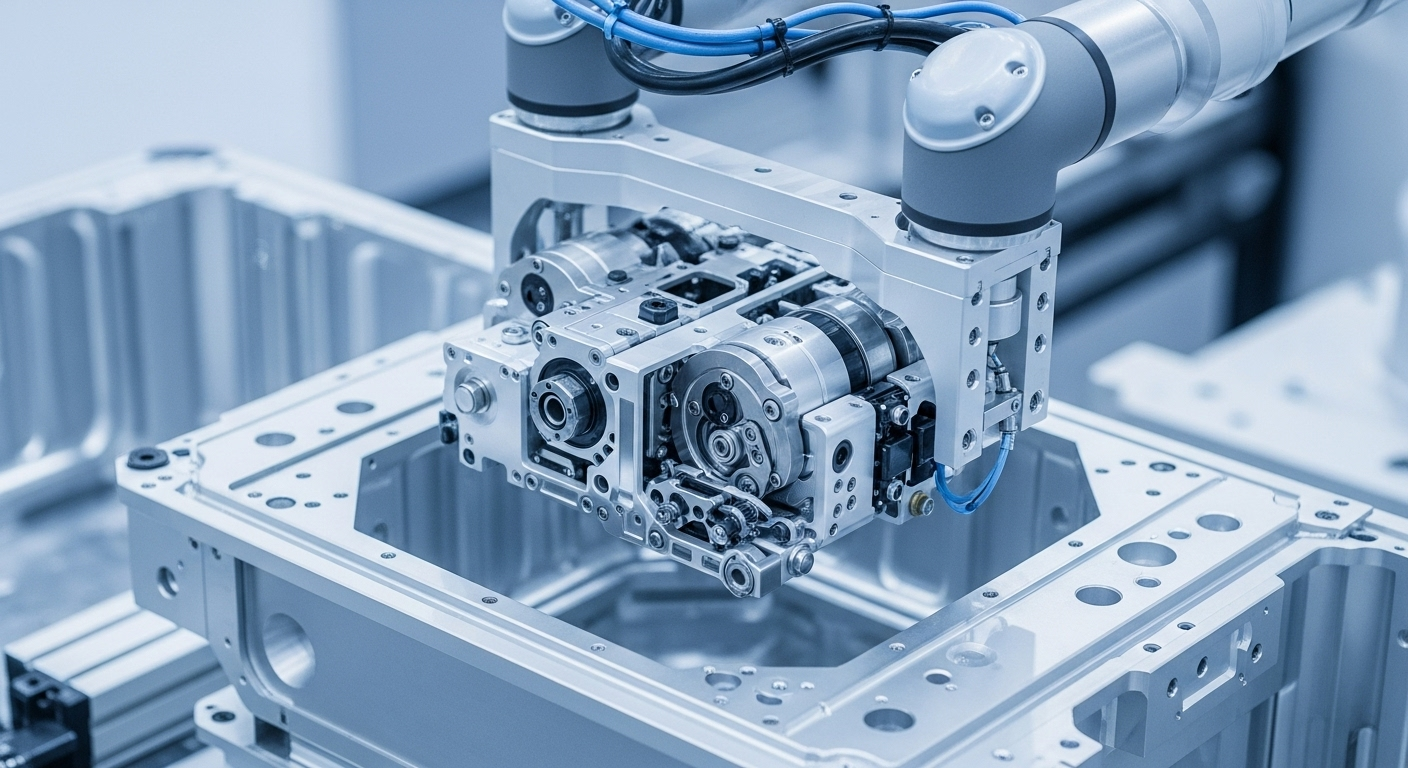

How do scheduling, quality, and automation factor in?

Maintenance work must align with production scheduling, quality objectives, and increasing levels of automation. Technicians coordinate with production planners to schedule downtime for preventative maintenance without causing undue interruptions. Awareness of quality metrics—defect rates, first-pass yield—helps prioritize fixes that reduce scrap and rework. As automation grows, technicians need skills in diagnosing electronic controls, sensor networks, and communication protocols. Familiarity with predictive maintenance data and basic troubleshooting of automated systems becomes more important in facilities that emphasize uptime and continuous operation.

Maintenance progression from operator to technician is a combination of deliberate skill-building, documented experience, and effective workplace collaboration. Operators who pursue relevant training, practice safe and ergonomic tool use, and learn inspection and calibration principles can move into roles that focus on equipment reliability and process support. Throughout this path, clear communication with production, quality, and engineering teams helps ensure maintenance activities align with broader manufacturing goals.