Steps to Prepare a Site for Backup Power Installation

Preparing a site for backup power involves a mixture of technical planning, regulatory compliance and operational readiness. This summary highlights key steps for assessing loads, choosing a suitable location, managing fuel, setting up monitoring and planning maintenance to ensure reliable uptime and system resilience.

Preparing a facility for backup power installation requires a structured project plan that aligns electrical requirements, site limitations and regulatory obligations. Early-stage planning should identify critical circuits and expected runtime so that equipment selection and installation reduce downtime and support long-term resilience. Considering noise control, fuel logistics, monitoring and lifecycle maintenance from the outset helps to ensure efficient operation and predictable uptime after commissioning.

Assessing power needs and load management

Begin with a detailed load assessment to determine which systems need backup and to set priorities for load management during outages. Calculate both running and starting currents, account for simultaneous loads and include a margin for future expansion. Correct generator sizing improves overall efficiency and reduces unnecessary fuel use. Specify transfer switch strategy—automatic transfer to preserve critical services and staged load shedding to extend runtime on limited fuel supplies.

Site selection for installation and noise control

Select a location that provides adequate ventilation, safe exhaust routing and structural support for plant. Consider access for deliveries and maintenance and ensure separation from combustible materials. Local planning rules and noise control regulations may require acoustic enclosures or other mitigation; consult local services early to confirm permitted noise levels and any planning permissions. Good siting reduces installation complexity and helps meet environmental and community expectations.

Fuel storage, handling and fuel safety

Develop a fuel strategy based on required autonomy and delivery frequency. On-site storage tanks must comply with environmental and fire-safety regulations and should include secondary containment and leak detection where appropriate. Implement fuel quality management—filtration, periodic testing and regular turnover—to prevent contamination and microbial growth. Formalise secure refuelling procedures, spill-response plans and training so fuel handling aligns with compliance and safety requirements.

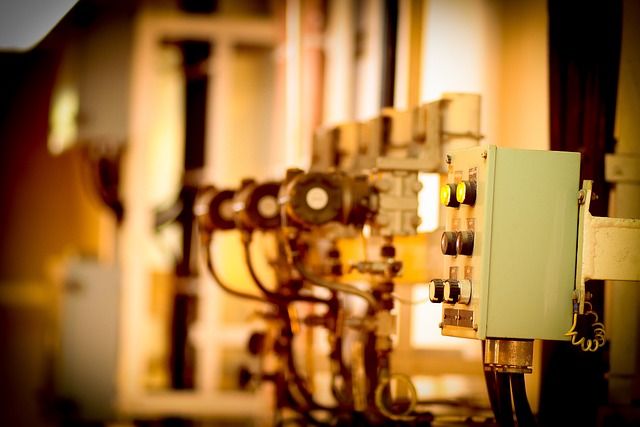

Monitoring, integration and system resilience

Integrate monitoring to track run hours, fuel level, battery condition, oil pressure and temperatures. Aim to connect generator telemetry with building management systems or SCADA to centralise alarms and logging. Ensure secure network architecture and clear escalation protocols for alerts to operations staff or local services. Effective monitoring enables predictive maintenance, improves response times during incidents and quantifies uptime performance for resilience planning.

Maintenance planning and lifecycle efficiency

A documented maintenance regime preserves efficiency and extends the lifecycle of backup assets. Routine tasks should include oil and filter changes, battery inspections, coolant checks and exercise runs to prevent component degradation. Maintain an inventory of critical spare parts and engage qualified technicians for specialist work. Align maintenance intervals with manufacturer guidance and adjust based on operational data to optimise lifecycle costs while maintaining reliability.

Commissioning, compliance and uptime verification

Commissioning confirms that installation and controls operate safely and to specification before handover. Execute load tests at varying levels, validate transfer sequences, verify protection settings and confirm noise control measures meet local limits. Keep comprehensive test records and certificates to demonstrate compliance with regulatory bodies and insurers. Proper commissioning establishes an operational baseline that supports predictable uptime and informs future maintenance and integration choices.

In summary, preparing a site for backup power installation combines technical assessment, careful siting, secure fuel management, robust monitoring and disciplined maintenance. Early attention to integration and compliance reduces installation risk and supports effective commissioning, while lifecycle and noise-control measures contribute to long-term resilience and operational efficiency without compromising safety or local obligations.